Understanding Con Rods: A Critical Component of Diesel Engine Performance

The diesel engine is a marvel of engineering, delivering exceptional power and efficiency under rigorous conditions. At the core of this powerhouse is the connecting rod, commonly referred to as the con rod. This article explores the vital role con rods play within diesel engines, their structure, functionality, and why choosing high-quality parts from suppliers like Client Diesel is essential for optimal performance.

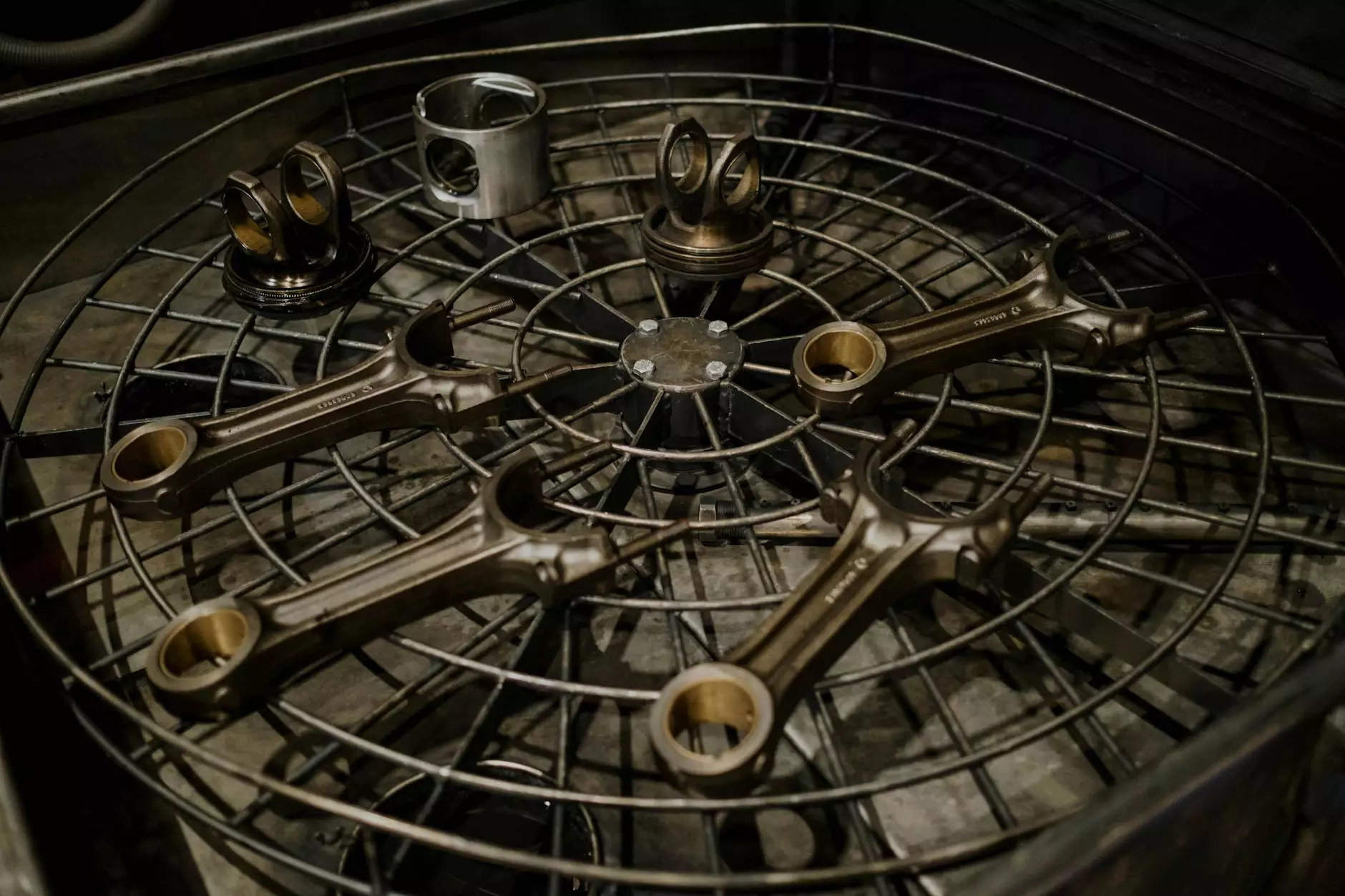

What is a Con Rod?

A connecting rod is a crucial component that links the piston to the crankshaft in a diesel engine. It translates the linear motion of the piston into the rotational motion required to drive the engine, functioning efficiently under extreme conditions of stress and heat. The relationship between the piston and crankshaft is fundamental to the power generation process, making the con rod a pivotal part of engine performance.

Key Functions of the Connecting Rod

The primary functions of a connecting rod include:

- Transmitting Forces: The con rod transmits the forces generated by the combustion of fuel in the piston to the crankshaft, facilitating movement and energy transfer.

- Maintaining Piston Alignment: It keeps the piston aligned, ensuring smooth movement within the cylinder while preventing side forces that could lead to excessive wear.

- Cooling: As the con rod moves, it helps dissipate heat generated during the combustion process, contributing to engine cooling. This is vital to prevent overheating and extend engine life.

Types of Connecting Rods

Connecting rods can be categorized based on their design and manufacturing processes. Understanding these types is crucial for selecting the right con rod for your diesel engine:

1. Forged Connecting Rods

These rods are manufactured through a forging process, which enhances their strength and durability. Forged con rods are typically found in high-performance engines due to their ability to withstand higher stress levels.

2. Cast Connecting Rods

Cast connecting rods are produced by pouring molten metal into molds. While generally cheaper and suitable for standard vehicles, they do not offer the same level of strength as forged rods. They are often used in engines with lower performance requirements.

3. Billet Connecting Rods

Billet con rods are made from solid bars of metal that are machined to specification. These are often the preferred choice for custom high-performance engines where precise specifications are required for peak performance.

The Importance of Quality in Connecting Rods

When it comes to diesel engines, the importance of using high-quality con rods cannot be overstated. High-quality connecting rods provide numerous benefits:

- Improved Performance: Performance is paramount in diesel engines. High-quality rods enable better power transfer and smoother operation.

- Enhanced Durability: Quality materials and manufacturing processes yield rods that resist wear and fatigue, ultimately prolonging engine life.

- Reliability: When operating under high load conditions, reliable con rods prevent catastrophic failures that could devastate engine integrity.

- Cost-Effectiveness: While high-quality parts may come at a higher initial cost, they often lead to savings in maintenance and repairs in the long run.

Signs of a Failing Connecting Rod

Understanding the signs of a failing connecting rod is critical for timely maintenance and avoiding significant damage to the engine:

- Unusual Noises: If you hear knocking or tapping sounds from the engine, it could indicate a failing con rod.

- Engine Vibration: Excessive vibrations during operation often signal issues with the connecting rod.

- Loss of Power: A pronounced decrease in engine power or responsiveness may also be attributed to failing components, including the connecting rod.

How to Choose the Right Connecting Rod

When selecting a connecting rod for your diesel engine, consider the following factors:

1. Engine Specifications

Always ensure that the con rod matches the engine specifications. Compatibility is crucial for performance and safety.

2. Intended Use

Determine whether the engine is for standard use or high-performance applications. This will influence whether you need forged, cast, or billet connecting rods.

3. Material Quality

Invest in rods made from high-quality materials. Look for manufacturers who provide specifications and certifications for their products.

The Role of Manufacturers and Suppliers

Trusted suppliers like Client Diesel offer high-quality diesel engine parts, including connecting rods. Their focus on quality ensures that customers receive durable and reliable components no matter the application.

Choosing the right supplier is crucial for any repair or rebuild project. Here’s why sourcing from reputable suppliers like Client Diesel matters:

- Quality Assurance: Established suppliers typically guarantee the quality of their products, ensuring peace of mind.

- Expert Guidance: They provide expert advice on selecting the right parts for your specific needs, helping you make informed decisions.

- Comprehensive Range: A wide range of products means you can find everything you need for your diesel engine under one roof.

Conclusion

The connecting rod is more than just a component; it is an integral part of a diesel engine's anatomy that significantly impacts performance. Understanding the characteristics and functions of high-quality con rods helps ensure optimal engine performance and longevity. By relying on reputable suppliers like Client Diesel, you ensure the best parts for your diesel engine, safeguarding your investment and enhancing efficiency.

Investing in quality connecting rods and other engine parts will provide the reliability you need to succeed in today's competitive market. Always aim for high performance and durability when choosing components for your diesel engine.

https://client-diesel.com/en/products/con-rod