Unlocking the Future of Business: Electronics, 3D Printing, and the Vital Role of Cement Silos in Industrial Innovation

In today’s rapidly evolving industrial landscape, businesses are leveraging the latest advancements in technology to foster innovation, increase productivity, and ensure sustainable growth. Companies operating in the fields of electronics and 3D printing are at the forefront of this revolution, transforming traditional manufacturing processes into high-efficiency, environmentally friendly operations. An essential yet often overlooked component in large-scale manufacturing setups—particularly in infrastructure and production facilities—is the cement silo. Understanding this equipment and its critical importance can unlock new levels of efficiency and scalability for your business.

Business Opportunities in Electronics and 3D Printing

The sectors of electronics and 3D printing are among the fastest-growing technological domains. They present vast opportunities for entrepreneurs, established companies, and startups alike. With advancements in materials, manufacturing techniques, and automation, these industries are shaping a new era of innovation.

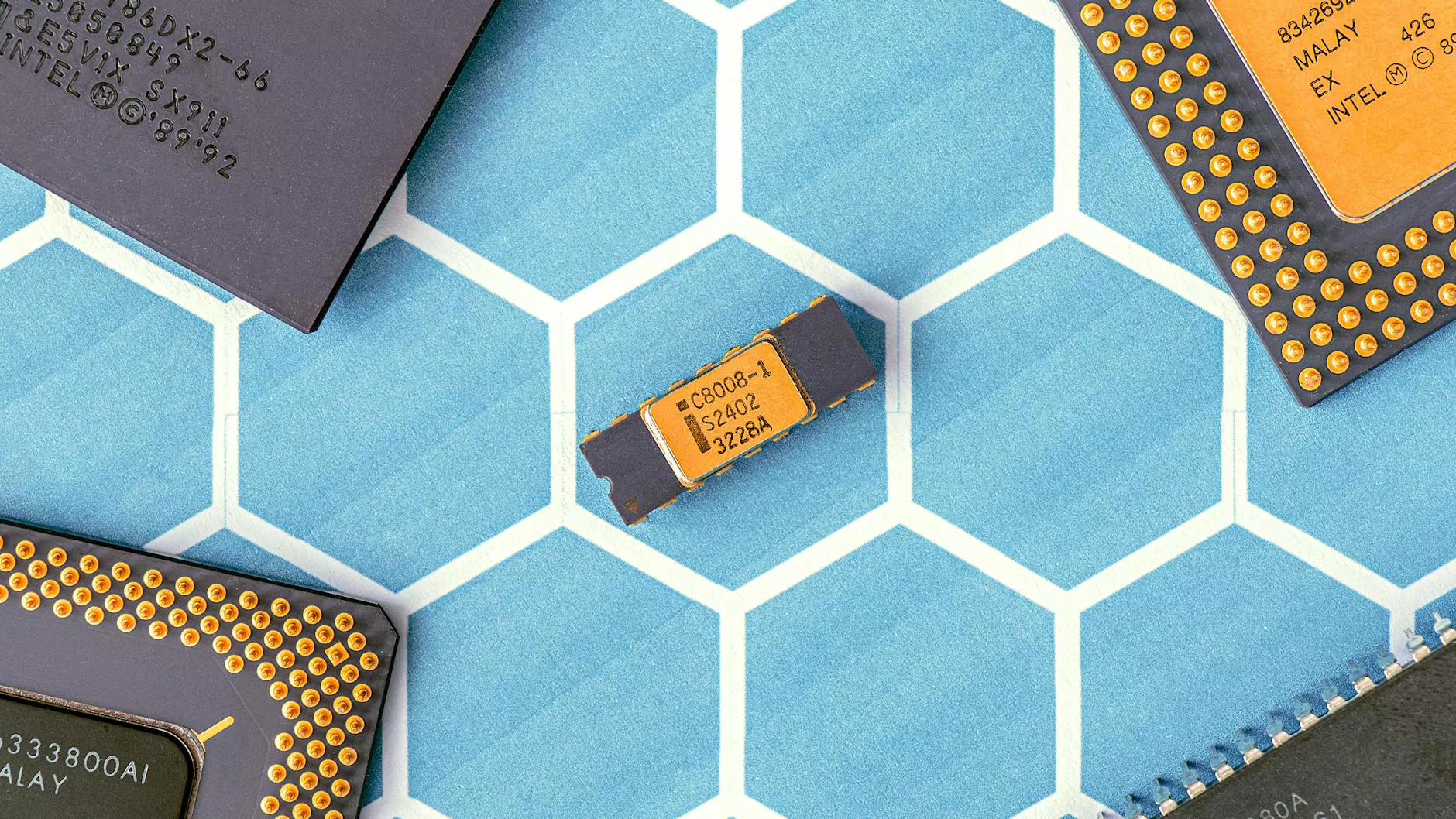

The Electronics Industry: Powering the Digital Age

The electronics sector forms the backbone of modern civilization. From consumer gadgets to industrial automation, electronics influence every aspect of life. Companies investing in innovative electronics manufacturing can capitalize on emerging markets such as IoT devices, wearable technology, and renewable energy systems.

- Product Development: Superior design and miniaturization of circuit boards

- Smart Manufacturing: Automating production lines with robotics and AI

- Supply Chain Optimization: Utilizing IoT for inventory and logistics management

The 3D Printing Revolution: Transforming Production

3D printing — also known as additive manufacturing — offers unparalleled flexibility, precision, and cost reduction in producing complex components. It enables rapid prototyping, custom manufacturing, and even mass production of intricate parts with minimal waste. This technology is revolutionizing industries such as aerospace, healthcare, automotive, and consumer goods.

- Customized product development with faster turnaround times

- Reduction of material waste and energy consumption

- Decentralized manufacturing and on-demand production

Integrating Advanced Manufacturing Infrastructure for Business Success

To fully capitalize on opportunities in electronics and 3D printing, businesses must equip themselves with robust manufacturing infrastructure. This includes the integration of large-scale equipment such as cement silos that are vital for managing raw materials like cement, fly ash, and other powders used in construction, ceramics, and specialized manufacturing processes.

The Critical Role of Cement Silos in Manufacturing Facilities

Cement silos are indispensable components in many industrial plants. They provide a secure, efficient, and scalable solution for storing bulk materials essential in construction and material processing industries. Their strategic importance extends beyond basic storage, affecting production efficiency, safety, and cost management.

Design and Features of Modern Cement Silos

Modern cement silos are designed with advanced features to support heavy-duty industrial applications. They feature high durability with corrosion-resistant coatings, integrated aeration systems to prevent material segregation, and automated loading and unloading mechanisms to optimize throughput. Some key advantages include:

- High Capacity: Large storage volumes to support continuous production

- Automation Compatibility: Enables integration with digital control systems

- Safety Features: Prevent spillages, dust emissions, and structural failures

Benefits of Using Cement Silos in a Modern Business Environment

Implementing high-quality cement silos can significantly enhance operational efficiency for manufacturing plants. Benefits include:

- Cost Efficiency: Reduced labor and material handling costs

- Improved Supply Chain Management: Consistent raw material availability

- Environmental Compliance: Minimized dust and spillage, supporting eco-friendly operations

- Scalability: Easily expand storage capacity to meet future demands

Choosing the Right Cement Silo for Your Business

Selecting the appropriate cement silo depends on your specific operational needs. Factors to consider include capacity, space constraints, environmental regulations, and integration capabilities with existing equipment.

Key considerations include:

- Material Compatibility and Durability

- Ease of Maintenance

- Automation and Control Integration

- Compliance with Industry Standards and Local Regulations

How PolygonMach Leads in Providing Cutting-Edge Solutions

PolygonMach specializes in manufacturing state-of-the-art industrial equipment that meets the highest standards of quality and innovation. Our portfolio includes top-grade cement silos, advanced electronics, and custom solutions tailored for the 3D printing industry. With decades of expertise, we empower businesses to streamline their operations and achieve unprecedented levels of productivity.

Our Commitment to Innovation and Quality

We leverage the latest manufacturing techniques and materials to create durable, reliable products that outperform industry norms. Our cement silos are engineered for maximum efficiency, safety, and environmental compliance, ensuring that your business stays ahead in a competitive market.

Comprehensive Support and After-Sales Service

Beyond providing equipment, PolygonMach offers comprehensive consulting, customization, and after-sales support. Our team works closely with clients from initial design to installation and ongoing maintenance, guaranteeing minimal downtime and peak operational efficiency.

Future Business Trends: Embracing Technology for Sustained Growth

As the fields of electronics and 3D printing evolve, businesses must adopt innovative infrastructure solutions, including high-quality cement silos, to remain competitive. Harnessing automation, digital integration, and sustainable practices will be key drivers in the next decade.

Adopting a Digital Manufacturing Ecosystem

The integration of IoT, AI, and data analytics into manufacturing processes can significantly boost productivity and reduce waste. Using smart cement silos equipped with sensors allows real-time monitoring of material levels, temperature, and structural integrity, enabling predictive maintenance and seamless operations.

Emphasizing Sustainability and Environmental Responsibility

Modern business leaders recognize that sustainable practices not only protect the environment but also improve brand reputation and operational costs. Choosing eco-friendly cement silos that minimize dust and emissions aligns with global green initiatives.

Conclusion: Building a Business Foundation for the Future

In conclusion, thriving in the competitive landscape of electronics and 3D printing requires more than just innovative products. It demands robust, efficient, and sustainable manufacturing infrastructure — with cement silos playing a critical role. Partnering with experienced providers like PolygonMach ensures that your business is equipped with the highest quality equipment, innovative technology, and strategic support necessary for long-term success.

Embrace the opportunities offered by these advanced sectors and invest in reliable, scalable infrastructure to propel your business into a future marked by growth and innovation.